Redefining Precision Engineering through Deburring Technology

Modern industries rely on components that are flawless, accurate, and meet international quality benchmarks. Whether it’s aerospace, medical, electronics, or automotive, manufacturers demand metal parts that are smooth and burr-free. This is where a deburring machine plays a pivotal role. It ensures components are finished with precision, enhancing their function, safety, and longevity. Globally trusted by industry leaders, this advanced solution has become an essential part of manufacturing units focused on reliability and high performance.

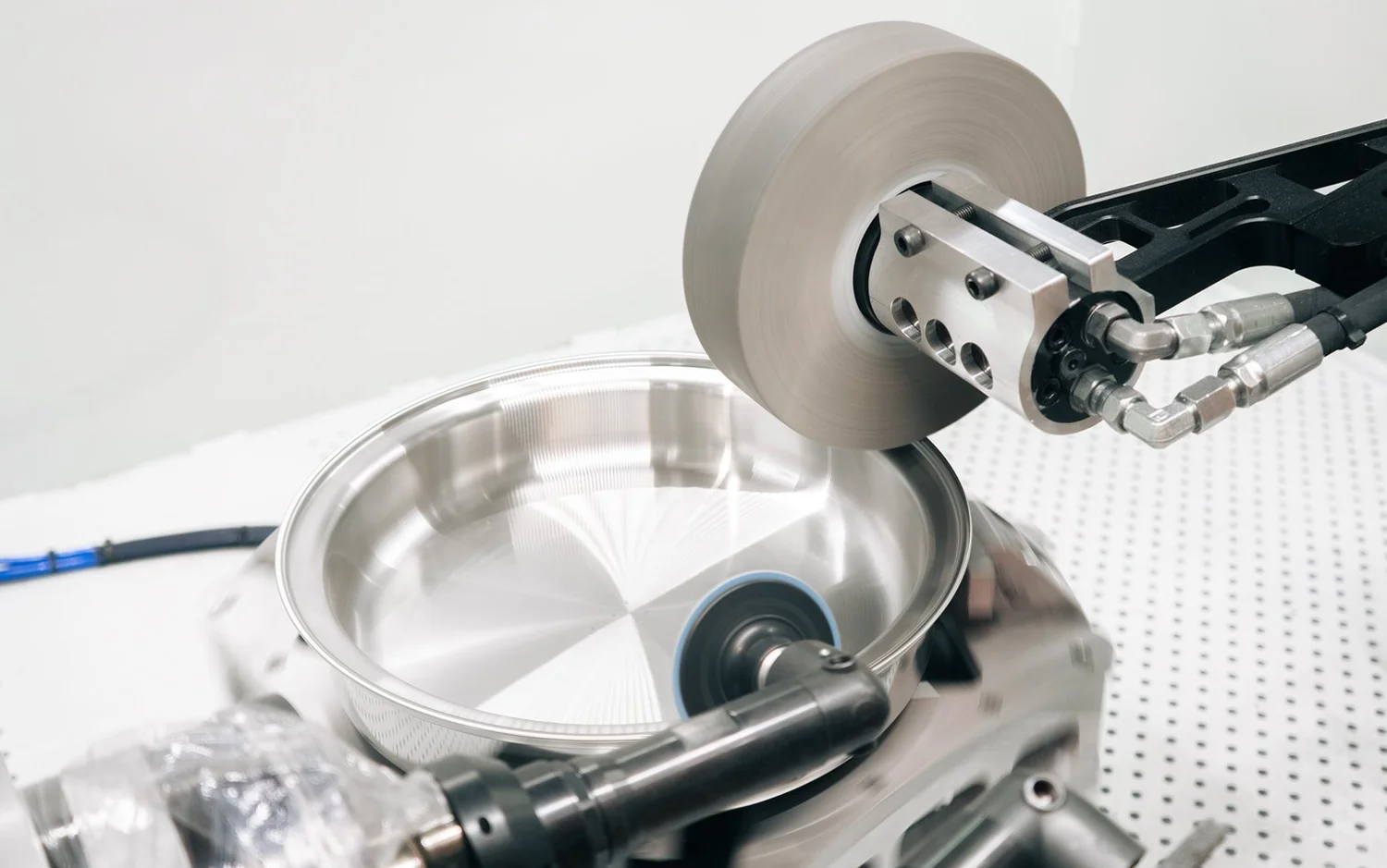

Elevating Component Quality with Consistent Finishing

The presence of burrs can hinder assembly, compromise safety, and impact mechanical performance. A deburring machine eliminates such imperfections through automated processes that guarantee uniformity across batches. These machines are designed to handle different geometries and materials, making them ideal for complex industrial needs. With the right configuration, a deburring solution can manage intricate contours, sharp edges, and varying thicknesses, ensuring the final product meets rigorous specifications.

Streamlined Efficiency for Global Manufacturing Standards

Efficiency is no longer optional—it’s a necessity. A deburring machine increases productivity by replacing manual edge finishing with automated, high-speed processes. Manufacturers across the globe trust this technology to meet high output demands while maintaining tight tolerances. It allows continuous operation with minimal downtime, significantly reducing operational costs. As the demand for zero-defect parts continues to rise, companies invest in these machines to stay ahead in global competition.

Trusted by Industry Leaders Worldwide

From Europe to Asia and across the Americas, leading OEMs and Tier 1 suppliers rely on the performance of a deburring machine to meet compliance standards. These machines support a wide range of applications, from stainless steel panels to aluminum die-castings and precision electronic housings. The ability to integrate seamlessly into production lines and work with robotic systems adds to their value in smart manufacturing environments. Their role in enhancing product quality and speed to market makes them indispensable in global production chains.

Innovation Driving Deburring Machine Capabilities

Over the years, technology within the deburring machine space has evolved remarkably. Today’s systems offer more than just edge removal—they provide controlled surface finishing, oxide layer removal, and even surface texturing. Equipped with adjustable speed settings, abrasive brush technology, and customizable programs, these machines adapt to varying industrial demands with ease. Such innovation not only boosts quality but also reduces human error and fatigue, resulting in safer working conditions and greater throughput.

Enhancing Component Integrity through Advanced Engineering

Mechanical integrity is vital, especially in sectors where failure is not an option. A deburring machine plays a crucial role in ensuring that components meet structural and functional criteria. Burrs and sharp edges are not just cosmetic issues—they can lead to stress concentration, misfitting parts, or electrical shorts. By removing these inconsistencies, the machine supports overall product reliability, making it a cornerstone for industries focused on safety and performance.

Sustainability and Repeatability in Metal Processing

Sustainable manufacturing is now a top priority. A deburring machine reduces material waste by processing components with precision, eliminating the need for rework or excessive grinding. Many modern models are energy-efficient and support eco-friendly production lines. Additionally, the repeatability of these machines means that each component produced adheres to the same high standard, regardless of volume. This makes it easier for manufacturers to maintain quality certifications and meet green manufacturing goals.

Conclusion: A Future-Proof Investment for Precision Manufacturing

Choosing the right deburring machine is not just an equipment purchase—it’s a strategic investment in long-term product quality, operational efficiency, and global competitiveness. Trusted by top-tier manufacturers around the world, these machines offer unmatched performance in creating burr-free, precision-finished components. Their adaptability, consistency, and advanced engineering make them a vital part of any forward-thinking production facility committed to delivering excellence.