Hairise plastic conveyor belt systems have become a vital solution in industries ranging from food processing to packaging, logistics, and manufacturing. These conveyor belts are designed to meet the growing demands for reliable, durable, and efficient transportation systems. Their versatility, coupled with the high-quality materials used in their construction, makes them an indispensable asset in modern production lines. Whether you’re working with delicate food products or heavy machinery parts, Hairise plastic conveyor belts provide smooth and reliable handling. With customizations available for different applications, these plastic conveyor belt are engineered to perform under various conditions. The ability of Hairise plastic conveyor belts to offer consistent performance across a range of industries is one of the key reasons they have gained widespread use. Their flexibility in design allows for the creation of conveyor systems that suit the specific needs of businesses. Whether it’s for high-speed transportation in the food sector or heavy-duty use in packaging, Hairise plastic conveyor belts excel in versatility. Their resistance to wear and tear also ensures a long lifespan, making them a cost-effective choice. When it comes to efficiency, precision, and sustainability, Hairise plastic conveyor belts have set the standard for modern conveyor solutions.

What Makes Hairise Plastic Conveyor Belt Systems Unique?

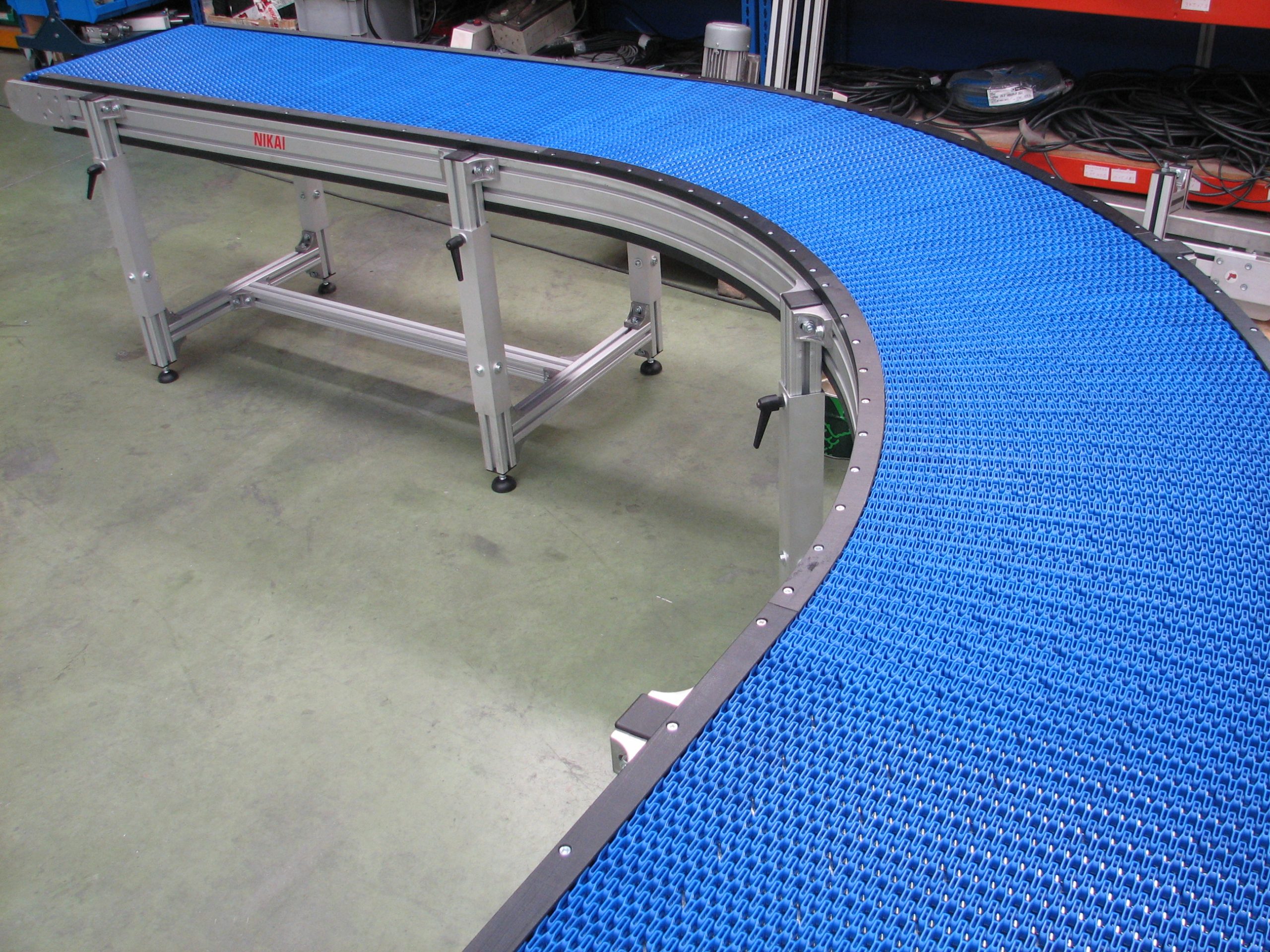

Hairise plastic conveyor belts are engineered with a deep understanding of industry needs. These belts are designed to handle a variety of products, from the most delicate food items to heavy industrial components. The belts are made from high-quality thermoplastic materials that are both durable and resistant to corrosion, making them suitable for both wet and dry environments. The modular design of Hairise plastic conveyor belts allows them to be configured into different shapes and sizes, ensuring they fit seamlessly into various production lines. This modularity is a significant advantage over traditional steel conveyors, which may require complex modifications. Furthermore, Hairise plastic conveyor belts feature smooth surface finishes that reduce friction, ensuring faster and more efficient product movement. This aspect is particularly beneficial in high-speed production lines, where time and accuracy are of the essence.

Advantages of Hairise Plastic Conveyor Belts in the Food Industry

The food industry demands strict hygiene standards, and Hairise plastic conveyor belts meet these requirements with ease. These conveyor belts are not only designed to be easy to clean but are also resistant to the accumulation of bacteria, making them ideal for food handling. Their smooth, non-porous surface prevents contaminants from adhering to the surface, ensuring that food products are transported safely and hygienically. Furthermore, Hairise plastic conveyor belts are resistant to oils, fats, and acids, making them an excellent choice for environments where such substances are common. This resistance to chemical exposure extends the lifespan of the belts, even in harsh conditions. The ability to withstand temperature fluctuations is another advantage of Hairise plastic conveyor belts in the food industry. These belts can operate effectively in both freezing and high-temperature environments, making them perfect for various stages of food processing, from freezing to baking.

Hairise Plastic Conveyor Belts in Packaging and Logistics

Hairise plastic conveyor belts also find significant application in packaging and logistics industries. The speed and efficiency of these belts are vital in handling goods through high-volume packaging systems. Whether you are dealing with small items like bottles and cans or large products like cardboard boxes, Hairise plastic conveyor belts can be customized to suit the specific requirements of the packaging line. Their robust construction ensures that they can handle heavy loads without compromising performance. In the logistics sector, the need for quick and reliable transportation of goods is paramount. Hairise plastic conveyor belts help streamline the movement of products through warehouses and distribution centers, improving overall operational efficiency. The modularity of Hairise plastic conveyor belts means they can be easily integrated into existing conveyor systems, making upgrades or expansions simpler and more cost-effective.

Durability and Maintenance of Hairise Plastic Conveyor Belts

One of the most significant benefits of Hairise plastic conveyor belts is their durability. These belts are built to last, with materials designed to withstand wear and tear over extended periods of use. Their resistance to abrasion means that they maintain their functionality even under heavy loads or harsh environments. The low-maintenance nature of Hairise plastic conveyor belts is another advantage. Unlike metal conveyor belts that require frequent lubrication and maintenance, plastic conveyor belts require minimal upkeep, reducing operational costs and downtime. In the event of damage, the modular design of these belts allows for easy repairs or replacements, further enhancing their cost-effectiveness. Additionally, Hairise plastic conveyor belts are designed to be energy efficient, helping businesses reduce their carbon footprint while improving the overall efficiency of their production lines.

Customization Options for Hairise Plastic Conveyor Belts

Hairise understands that no two businesses are the same, which is why their plastic conveyor belts can be tailored to meet the specific needs of each industry. Customization options include varying the width, length, and even the type of plastic used to ensure that the conveyor belt performs optimally in a given environment. For example, if you are working with particularly sticky or fragile products, Hairise plastic conveyor belts can be designed with surface treatments or coatings that prevent products from sticking. If your application requires extra traction, Hairise plastic conveyor belts can be equipped with textured surfaces to ensure better grip. Additionally, the modular nature of these conveyor belts means that businesses can easily adapt their systems as their production needs evolve over time. Customization allows businesses to design conveyor systems that maximize space utilization and minimize operational inefficiencies.

Conclusion: The Future of Conveyor Systems with Hairise Plastic Conveyor Belts

Hairise plastic conveyor belts represent the future of conveyor systems across multiple industries, from food processing to packaging and logistics. Their durability, efficiency, and versatility make them the ideal choice for modern production environments. With the ability to withstand harsh conditions, reduce maintenance needs, and improve overall efficiency, Hairise plastic conveyor belts are an investment that delivers significant returns over time. Whether you’re handling food products, delicate packaging, or industrial components, these plastic conveyor belts offer a reliable and sustainable solution for your transportation needs. The innovative designs and customizations available ensure that each business can create a tailored conveyor system that meets its specific requirements. As industries continue to evolve, Hairise plastic conveyor belts will play a critical role in optimizing production lines and ensuring that goods are transported safely and efficiently.